© 2026 Observater Surveys and Services Group. All rights reserved.

Bringing Clarity to Complex Cargo Operations

Located at the crossroads of major international shipping lanes, critical ports are the primary maritime gateways for entire regions. The high volume of container, bulk, and project cargo passing through their terminals demands expert oversight to mitigate risk, help prevent loss, and resolve disputes swiftly.

Observater provides a comprehensive suite of cargo survey and inspection services, leveraging our deep understanding of local port operations, customs procedures, and logistical challenges. Our presence on the ground helps protect your interests with unparalleled local expertise and global standards of excellence.

Complete Cargo Inspection & Quantification Services

We offer a full spectrum of survey and supervision services, employing a comprehensive array of internationally recognized methods to ascertain the quantity, quality, and integrity of your cargo at every stage. Our services are tailored to meet the specific demands of any cargo type or operational requirement.

Core Cargo Surveys & Investigations

When cargo incidents occur, a swift and expert response is crucial. Our team specializes in forensic investigations to ascertain the root cause of damage, contamination, or loss, providing clarity in complex situations. We deliver clear, evidence-based reporting that empowers our clients to effectively manage claims, determine liability, and support their financial standing.

-

Cargo Damage Surveys

Observater’s expert surveyors provide authoritative cargo damage surveys to meticulously ascertain the cause, nature, and extent of damage to your goods. We deliver clear, evidence-based reports, complete with photographic documentation and loss quantification, empowering insurers, P&I Clubs, and cargo owners to confidently manage claims and pursue recoveries.

-

Cargo Contamination Surveys

We specialize in cargo contamination surveys, crucial for liquid and dry bulk commodities. Our forensic analysis identifies the source, nature, and scope of contamination, whether from previous cargo, water ingress, or improper handling. Observater’s rapid response and detailed reporting help mitigate further losses and provide the necessary evidence for liability disputes.

-

Pre-shipment Inspections

Protect your interests before loading. Observater’s pre-shipment inspections verify that your cargo’s quantity, quality, and packing conform to all contractual specifications. Our independent reports, issued prior to shipment, provide essential assurance to buyers and financial institutions, preventing costly disputes upon arrival and ensuring compliance with international trade standards.

-

Outturn & Landing Surveys

Observater conducts thorough outturn and landing surveys to document the condition of cargo as it is discharged from the vessel. This service is vital for identifying any damage or loss that may have occurred during transit. Our immediate, on-site reporting provides a clear record of discharge operations, which is essential for claims handling.

-

Loss & Shortage Investigations

In cases of non-delivery or short-landing, Observater’s surveyors conduct meticulous investigations to trace the cargo and determine the cause of the loss. We reconcile shipping documents, tally records, and terminal reports to provide a comprehensive account, helping our clients substantiate claims and identify breaches in the supply chain.

-

Reefer & Perishable Cargo Surveys

Specializing in high-value perishable goods, Observater provides expert reefer cargo surveys. We verify pre-trip inspection (PTI) records, monitor temperature settings throughout transit, and assess the condition of cargo upon arrival. Our expertise is critical in determining the cause of spoilage, whether from equipment malfunction, improper stowing, or temperature deviation.

-

Liquid Cargo & Chemical Surveys

Our experienced surveyors are trained in the complexities of liquid cargo and chemical handling. We conduct precise quantity calculations, cleanliness inspections of tanks, and sampling in accordance with international standards (ASTM, ISO). We safeguard our clients’ interests during ship-to-shore transfers, tank-to-tank movements, and storage operations for petroleum products, chemicals, and vegetable oils.

-

Warehouse & Stockpile Inspections

Observater extends its expertise beyond the quayside with comprehensive warehouse and stockpile inspections. We assess storage conditions, cargo segregation, and inventory management practices. Our services include volumetric surveys for stockpiles and condition assessments for stored goods, providing critical data for insurers, lenders, and owners.

-

Robbery, Pilferage & Theft Investigations

When cargo security is breached, Observater provides discreet and thorough investigations into robbery, pilferage, and theft. Our team works to identify vulnerabilities in the supply chain, document losses, and gather evidence. Our objective reports assist in insurance claims, recovery efforts, and implementing stronger future security measures.

-

Investigation of Cause of Damage

Our primary role in damage surveys is the forensic investigation into the root cause. Observater’s surveyors are trained to look beyond the visible damage, analyzing stowage, lashing, weather reports, and handling procedures to determine *why* the damage occurred. This distinction is fundamental for all liability, subrogation, and claims resolution processes.

-

Hatch & Hold Sealing/Unsealing Surveys

To protect cargo integrity and establish a clear chain of custody, Observater provides hatch and hold sealing surveys. We verify the cargo is secure and apply high-security seals, documenting their numbers. Upon arrival, our unsealing survey confirms the seals’ integrity before discharge, providing key evidence in case of shortage or contamination claims.

-

Hold & Tank Cleanliness Inspections

A critical loss prevention measure, our cleanliness inspections ensure vessel holds and tanks are free from previous cargo residues, rust, or moisture. Observater surveyors verify that the cargo space is in a “ready to load” condition, protecting high-value commodities from contamination and helping clients meet charter-party obligations.

Loss Prevention, Supervision & Tally

Effective claim management benefits from proactive prevention. Observater acts as your partner on the ground, offering diligent supervision and precise tallying for all cargo operations. By overseeing key steps, from handling to stowage and securing, we help mitigate risks before they escalate, safeguarding your assets, reducing potential liabilities, and promoting a smooth supply chain.

-

Loading Supervision

Observater’s loading supervision services are your first line of defense against cargo damage. Our surveyors actively monitor the entire loading process, ensuring correct handling techniques, proper equipment use, and safe stowage. We intervene to stop improper practices, documenting the entire operation to protect you from liability for pre-existing damage.

-

Discharge Supervision

During discharge, our surveyors act as your eyes and ears on the vessel and quayside. We diligently monitor handling operations to prevent damage caused by stevedores or improper equipment. We document the condition of cargo as it’s landed, segregating damaged items and immediately notifying relevant parties to mitigate losses.

-

Tally Surveys (Cargo Clerking)

An accurate count is the foundation of cargo accountability. Observater provides independent and precise tally surveys, verifying cargo quantity (units, bags, bundles) during loading and discharge. Our meticulous cargo clerking services are essential for preventing shortage claims, conforming to Bill of Lading quantities, and resolving discrepancies immediately.

-

Stowage, Lashing & Securing Surveys

Improper securing is a leading cause of cargo damage at sea. Observater’s surveyors are experts in CSS Code compliance, verifying that cargo is correctly stowed, lashed, and secured for the intended voyage. We assess the suitability of lashing materials and patterns, providing recommendations to ensure the stability and safety of your cargo.

-

Project Cargo & Heavy Lift Supervision

For high-value, out-of-gauge, and project cargo, Observater provides specialized supervision. Our experts review lift plans, assess lifting gear, and monitor the entire loading or discharge operation. We focus on risk mitigation for these critical lifts, ensuring every movement is executed safely, in line with engineering specifications, and without incident.

-

Stuffing & De-stuffing Supervision (Containers)

We extend our supervision to container freight stations (CFS). Observater oversees the stuffing (loading) and de-stuffing (unloading) of containers, verifying quantity, checking for damage, and ensuring proper weight distribution and securing. This service is vital for LCL (Less than Container Load) shipments and for confirming the condition of goods at the point of consolidation.

-

Weighbridge Supervision

To ensure accurate weight certification for bulk or project cargo, Observater provides impartial weighbridge supervision. Our surveyors verify the calibration of the weighbridge, record all empty (tare) and full (gross) weights, and provide an independent, certified weight record. This service is critical for preventing commercial disputes based on quantity.

-

Sampling Supervision

Observater ensures that cargo sampling is conducted according to internationally recognized standards (e.g., GAFTA, FOSFA). We oversee the entire process to ensure representative samples are drawn, properly mixed, divided, and sealed. Our independent supervision provides all parties with a verified, contractual sample for quality analysis, preventing disputes over cargo specifications.

-

Labeling & Marking Verification

Correct labeling and marking are essential for regulatory compliance and proper cargo handling. Observater verifies that all cargo units are marked in accordance with shipping documents, contracts, and destination requirements (e.g., IMDG labels for dangerous goods). This simple check prevents costly delays, customs fines, and misidentification of goods.

-

Packing Condition Surveys

Inadequate packing is a primary contributor to cargo damage. Observater’s packing condition surveys assess whether the packing materials and methods are suitable for the cargo and the intended transit. We identify weaknesses in crates, cases, or bundling that could lead to damage, allowing for corrective action before shipment.

Cargo Quantification & Measurement Methods

Accuracy in cargo quantity is fundamental. Our surveyors employ a comprehensive range of internationally recognized measurement techniques, from traditional draft surveys to advanced gauging. We deliver impartial and definitive quantity reports that form a trusted basis for financial settlements, help avoid commercial disputes, and provide an indisputable record for stakeholders.

-

Draft Surveys (Initial, Intermediate, Final)

Observater is a leader in draft surveys, the most widely accepted method for determining the weight of bulk cargo. Our surveyors meticulously read the vessel’s draft marks, measure ballast and consumables, and apply hydrostatic corrections to calculate the cargo loaded or discharged. Our independent reports are the trusted basis for Bills of Lading and commercial invoices.

-

Ullage & Sounding Surveys

For liquid bulk cargo, Observater performs precise ullage and sounding surveys. Using calibrated equipment, we measure the free space (ullage) or liquid level (sounding) in vessel or shore tanks. We apply corrections for trim, list, and temperature to calculate the exact volume and weight of the cargo, ensuring accurate quantity determination.

-

Barge & Tank Gauging

Our gauging services for barges and shore tanks are essential for custody transfers. Observater provides independent, third-party measurements before and after transfer operations. We verify volumes against calibration tables, providing an impartial report that is vital for inventory control and resolving disputes between suppliers, terminals, and receivers.

-

Volumetric Surveys (Stockpiles & Cargo)

Observater utilizes modern survey techniques, including 3D laser scanning and traditional methods, to conduct volumetric surveys of stockpiles (coal, minerals, grains) and cargo in vessel holds. By creating a precise topographic model, we calculate the volume, which is then multiplied by an established density factor to determine the total tonnage.

-

On-Hire / Off-Hire Condition & Bunker Surveys

A crucial service for charterers and shipowners. Observater’s On-Hire/Off-Hire surveys document the vessel’s condition and precisely measure the quantity of bunkers (fuel) on board at the time of delivery or re-delivery. This impartial report protects our clients from disputes regarding vessel damage or bunker consumption during the charter period.

-

Deadweight Surveys

Observater performs deadweight surveys to determine the total weight of cargo a vessel has loaded by calculating the difference between its lightship displacement and its displacement after loading. This survey is a reliable method of cargo quantification, often used when draft surveys are complex or in conjunction with them for verification.

-

Flow Meter Verification

During liquid cargo transfers, Observater provides independent verification of flow meter readings. Our surveyors witness the opening and closing readings, check meter seals, and reconcile the meter-totaled quantity against shore tank or vessel measurements. This oversight ensures that the recorded transfer quantity is accurate and has not been tampered with.

-

Weight Determination by Silo Gauging

For bulk commodities like grains and cement, Observater provides weight determination via silo gauging. By taking precise measurements of the product level within the silo and applying the known bulk density, we can calculate the total tonnage. This is a common and accepted method for inventory control and quantity verification before vessel loading.

-

Bagged Cargo “Cutting and Weighing”

To determine the average weight of bagged cargo, Observater employs the “cutting and weighing” method. We take a representative sample of bags from the shipment, weigh them individually, and then weigh the empty bags to establish an accurate net weight. This average is used to calculate the total weight of the shipment based on the tally count.

-

Piece Counts & Tallying

As a fundamental quantification method, Observater provides independent piece counts and tallying. Our surveyors physically count every unit (e.g., steel coils, vehicles, crates) as it is loaded or discharged, reconciling the final count against the shipping manifest. This service is the most direct way to prevent and identify quantity discrepancies.

-

Scrap Metal Weight Surveys

Observater conducts scrap metal weight surveys, typically via draft survey or weighbridge supervision. Given the nature of the cargo, establishing an accurate weight is critical for all commercial parties. Our independent survey report provides a verifiable weight certificate that is trusted by both sellers and buyers for final payment settlement.

Specialized Commodity & Cargo Type Expertise

No two cargoes are the same, and our versatility reflects this reality. Our team possesses deep expertise across a vast array of commodity types, understanding the unique vulnerabilities of each. Whether you are shipping sensitive refrigerated goods, heavy industrial components, or bulk raw materials, we apply specialized knowledge to address specific risks, verifying proper handling, stowage, and transport.

-

Container Inspections (CSC, Damage, Reefer)

Observater provides comprehensive container inspections. We verify structural integrity (IICL standards), check CSC plates for validity, and assess cleanliness. For refrigerated containers, we confirm Pre-Trip Inspection (PTI) and temperature settings. This expertise ensures the container is fit for purpose and cargo-worthy, preventing losses during transit.

-

Flexitank Inspections (Fitting, Loading, Discharge)

We are specialists in flexitank operations for non-hazardous liquid bulk. Observater surveyors supervise the correct fitting of the flexitank within the container, monitor the entire loading or discharge process, and verify all seals and valves. Our supervision is critical for preventing leaks, spills, and contamination, protecting both the cargo and the environment.

-

ISO Tank Inspections

Observater’s surveyors conduct detailed inspections of ISO tanks for liquid bulk, chemicals, and gases. We verify the tank’s cleanliness, structural integrity, and the operational status of all valves and pressure-relief devices. We also check for valid test certificates, ensuring the tank is safe and suitable for transporting the specified product.

-

Steel Cargo Surveys (Coils, Plates, Pipes)

Steel products are highly susceptible to rust and physical damage. Observater provides expert pre-shipment condition surveys, supervision of loading to ensure proper handling, and stowage surveys to verify correct lashing and separation. Our outturn surveys meticulously document any rust, bending, or damage that occurred during the voyage.

-

Vehicle & Ro-Ro Cargo Surveys

For Roll-on/Roll-off (Ro-Ro) cargo, Observater provides condition surveys of vehicles, trucks, and heavy machinery at the time of loading and discharge. Our surveyors meticulously document any pre-existing scratches, dents, or damage, and verify that all units are properly lashed and secured for the sea voyage, protecting carriers from unfounded claims.

-

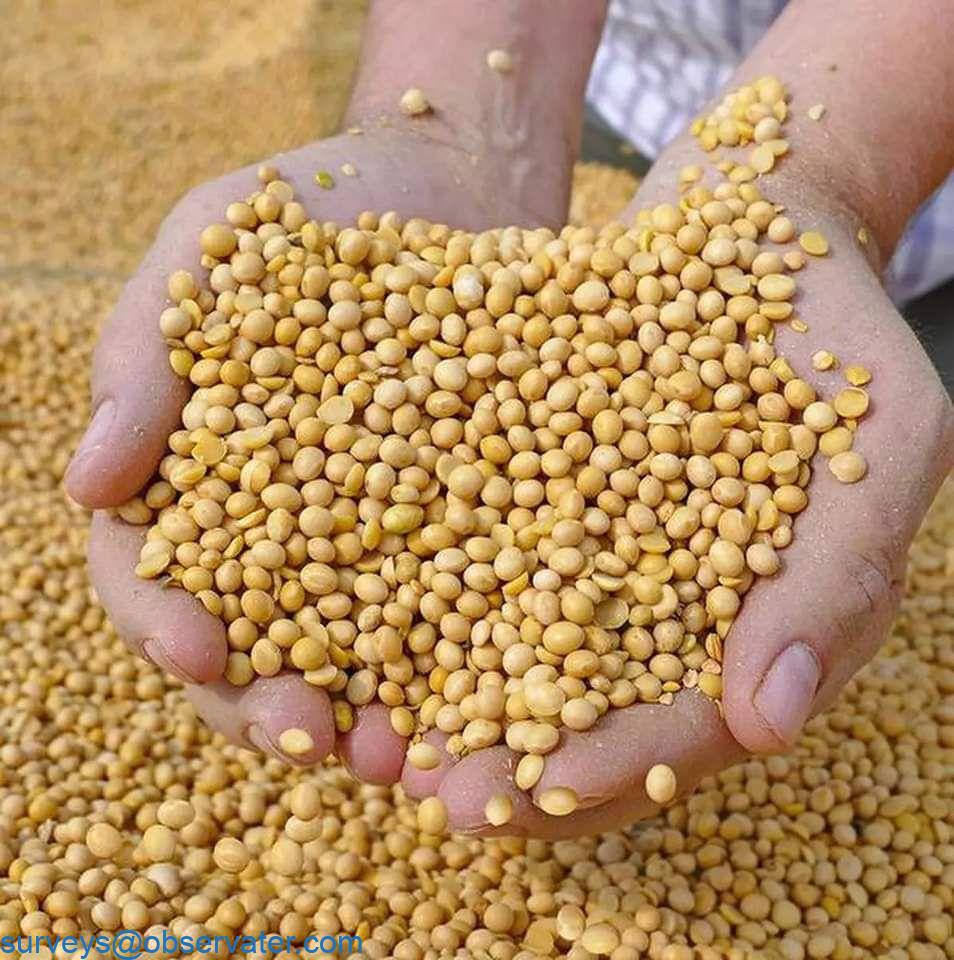

Grains & Agricultural Products Surveys

We are experts in agricultural commodities, providing services compliant with GAFTA and FOSFA standards. This includes hold cleanliness inspections, draft surveys for quantity, supervision of sampling for quality analysis, and monitoring for signs of heat, infestation, or moisture during loading and discharge of grains, pulses, and other products.

-

Fertilizer & Mineral Surveys

Observater offers specialized surveys for bulk fertilizers and minerals. We focus on draft surveys for accurate quantity, as well as representative sampling to test for moisture content and product specifications. We also monitor for caking or contamination, ensuring the product arrives in a commercially viable condition.

-

Coal & Pet-Coke Surveys

Our surveyors are experienced in handling coal and pet-coke shipments. We provide draft surveys for quantity and supervise the collection of representative samples for laboratory analysis of calorific value, moisture, and ash content. We also monitor for any signs of self-heating during loading, a critical safety check for this commodity.

-

Timber, Logs & Forest Product Surveys

Observater provides quantification and quality surveys for timber, logs, and other forest products. We are proficient in various measurement standards (e.g., Brereton, Doyle) to determine cargo volume. We also assess for physical damage, rot, or insect infestation, and supervise the proper lashing and securing of deck cargo.

-

Breakbulk & General Cargo Surveys

Our expertise covers all forms of breakbulk and general cargo. This includes pre-loading surveys to check condition and packing, tally services to verify quantity, and supervision of loading to ensure correct handling, stowage, and dunnaging. Our reports are essential for documenting the condition of goods at every point of transfer.

-

Liquid Bulk (Oil, Gas, Chemicals) Surveys

Observater’s highly trained inspectors provide precise quantity determination and quality control for high-value liquid bulk cargoes. Following API and ASTM standards, we perform tank gauging, temperature reading, and sampling. Our independent calculations of cargo quantity are trusted by traders, terminals, and owners for custody transfer and loss control.

Warehouse & Facility Inspections

Cargo integrity is not just a maritime concern. We extend our expertise to land-based storage facilities, providing critical assessments for insurers, cargo owners, and operators. Our inspections help identify risks, verify conditions, and confirm the suitability of warehouses for high-value goods.

-

Pre-lease / Pre-use Condition Surveys

Before committing to a lease, our surveyors conduct a detailed pre-use condition survey of the warehouse. We document the structural integrity, state of repair, and cleanliness of the facility. This independent report establishes a baseline condition, protecting our clients from liability for pre-existing damages when they exit the lease.

-

Facility Suitability & Risk Assessments

Observater assesses whether a storage facility is suitable for a specific commodity. We analyze factors like ventilation, moisture control, floor strength, and contamination risks. Our risk assessment report provides insurers and cargo owners with the critical information needed to determine if the facility meets the required standards of care.

-

Security & Access Control Audits

We provide comprehensive security audits for warehouses and storage yards. Our surveyors evaluate perimeter fencing, lighting, access control points, CCTV coverage, and alarm systems. This assessment identifies vulnerabilities to theft, pilferage, or unauthorized access, providing actionable recommendations to enhance the security of high-value goods.

-

Fire Safety & Suppression System Verifications

A critical component of warehouse risk, our fire safety verification inspects the facility’s fire mitigation measures. We check for functional fire extinguishers, sprinkler systems, smoke detectors, and clear emergency exits. We also assess cargo segregation practices to ensure compliance with fire codes, especially for flammable or hazardous materials.

-

Inventory & Stock Audits

Observater provides independent inventory and stock audits to verify quantities held in storage. Our team performs physical counts, reconciles findings with warehouse records, and documents the condition of the stock. This service is essential for financial auditing, collateral management, and asset verification for lenders and insurers.

-

Stockpile Measurement & Verification

Using 3D laser scanning or traditional methods, our surveyors accurately measure the volume of bulk commodity stockpiles in warehouses or open yards. By applying a verified density factor, we provide an independent calculation of the total tonnage. This is vital for inventory financing, stock audits, and resolving quantity disputes.

-

Goods Condition & Storage Surveys

We conduct periodic surveys of goods in storage to monitor their condition over time. Our surveyors check for signs of damage, deterioration, moisture, or pest infestation. We also assess the storage methods, such as stacking height and dunnage, to ensure they are appropriate and not contributing to cargo damage.

-

Damage & Contamination Assessments

In the event of a fire, flood, or contamination incident within a warehouse, Observater is deployed to assess the extent of the damage. We segregate affected from non-affected goods, quantify the losses, and investigate the root cause. Our reports are essential for initiating insurance claims and planning salvage operations.

-

Pest Control & Cleanliness Inspections

Especially critical for foodstuffs and agricultural products, our inspections verify the cleanliness of the warehouse. We check for evidence of pests, birds, or rodents and review the facility’s pest control program. This ensures the storage environment is hygienic and will not lead to cargo contamination or regulatory issues.

Container Inspection Services

With the vast majority of goods transiting ports in containers, verifying their integrity is paramount. Our dedicated container inspection services check that units are structurally sound, clean, and fit for purpose, helping to mitigate risks of cargo damage from water ingress, contamination, or equipment malfunction. We provide assurance at critical points of the container’s journey.

-

Pre-loading condition surveys

Observater inspects empty containers prior to stuffing. We verify they are structurally sound, dry, and free from any residues, odours, or pests from the previous cargo. This simple check is a critical loss prevention step, ensuring the container is cargo-worthy and will not damage your goods during transit.

-

Structural integrity inspections (IICL standards)

Our surveyors are trained to assess container condition based on IICL (Institute of International Container Lessors) standards. We identify structural damages like bent frames, punctured panels, or faulty door gaskets that could compromise cargo safety or allow water ingress. This is essential for high-value or sensitive cargo.

-

Cleanliness and odour-free verification

Especially vital for foodstuffs, pharmaceuticals, and other sensitive goods, our surveyors enter the container to verify it is completely clean and free of any foreign odours. This prevents cross-contamination from previous cargoes, which can render an entire shipment worthless even without physical damage.

-

Reefer Pre-Trip Inspection (PTI) monitoring

For reefer containers, we independently verify that a valid Pre-Trip Inspection (PTI) has been successfully completed. We check that the temperature is set according to your instructions and that the datalogger is active. This confirms the machinery is fully operational before your perishable cargo is loaded.

-

Stuffing, Lashing & Securing Supervision

Observater oversees the entire container stuffing process. We ensure your cargo is handled correctly, stowed properly to maximize space and stability, and not mixed with incompatible goods. We meticulously supervise the lashing and securing of the cargo within the container to prevent shifting and damage during the ocean voyage.

-

Seal Integrity Verification (Application & Removal)

The container seal is the primary evidence of security. Observater surveyors document the application of high-security seals at stuffing, verifying the seal number matches the shipping documents. Upon arrival, we conduct a seal integrity check before removal, providing a clear chain of custody and protection against claims of theft or pilferage.

-

Cross-stuffing / Trans-loading supervision

During trans-loading (moving cargo from one container to another), Observater provides critical supervision. We tally the cargo as it is moved, document its condition, and supervise the re-stuffing and sealing of the new container. This ensures cargo integrity and quantity are maintained during this high-risk transfer point.

-

CSC Plate validation and checks

Our surveyors perform validation of the container’s CSC (Convention for Safe Containers) plate. This check confirms that the container has a valid safety approval and is within its certification date. This is a crucial step for regulatory compliance and verifying the container is legally and safely operable for international transport.

From the Field

A glimpse into our daily operations, showcasing our hands-on approach to protecting our clients’ interests worldwide.

Local Expertise, Global Capacity

Our greatest strength lies in our unique structure: deep-rooted local expertise across key African markets combined with the reach and resources of a global network. This allows us to offer clients the best of both worlds.

- Local Intelligence: Our on-ground teams possess invaluable familiarity with the operational procedures, key personnel, and potential challenges at specific ports.

- Rapid Deployment: We can be on-site within hours of your instruction, helping preserve critical evidence and minimize delays.

- Unwavering Independence: We provide strictly impartial, factual reports that are trusted by P&I Clubs, underwriters, shipowners, and cargo interests alike.

- International Standards: All surveys are conducted to high international standards, ensuring our reports are recognized and respected globally.

- Seamless Coordination: We provide a single point of contact for complex, multi-port, or multi-jurisdictional assignments, simplifying communication and promoting consistent quality.

Protect Your Cargo

Whether you require an urgent damage survey or proactive loss prevention supervision, our team is ready to assist. Contact us to appoint a surveyor anywhere in the world.

Appoint a Surveyor