© 2026 Observater Surveys and Services Group. All rights reserved.

Independent Bunker Surveyors Across Africa

In the complex bunkering hubs of Africa, a slight variance in measurement can cost thousands of dollars. You need an independent eye on the manifold. Observater Africa is the continent’s leading network of independent bunker surveyors.

We verify quantity and quality at over 85 strategic ports in Africa, including the offshore anchorage hubs of West Africa (Lomé, Lagos) and the key transit ports of Southern and East Africa (Durban, Richards Bay, Mombasa, Port Louis). Whether you are a Shipowner, Charterer, or Bunker Trader, our 24/7 rapid-response surveyors ensure you receive exactly what you paid for.

Charterers & Owners

On-Hire & Off-Hire Bunker Surveys (ROB)

The transition of a vessel between Owner and Charterer is a critical financial moment. An On-Hire Survey or Off-Hire Survey by Observater Africa provides the impartial, certified evidence needed to settle fuel accounts.

Our surveyors board vessels at any African port—from Casablanca to Cape Town—to conduct a rigorous sounding of all fuel tanks. We calculate the exact Remaining on Board (ROB) quantity, applying precise temperature and density corrections. Our report is the definitive document for your Charter Party agreement, preventing costly disputes over fuel quantity.

Stem Supervision

Bunker Quantity Surveys (BQS) / Stem Supervision

Refueling in ports like Lomé (Togo), Durban (South Africa), or Port Louis (Mauritius) requires vigilance. Our Bunker Quantity Survey (BQS) service places an expert surveyor on board to supervise the entire stem.

We verify the barge’s measurements before and after delivery, check for the “cappuccino effect” (air in the line), and monitor manifold pressures. By independently verifying the delivered quantity against the Bunker Delivery Note (BDN), we protect you from short-delivery claims and ensure you only pay for the fuel that actually entered your tanks.

Loss Control

221B Surveys / Bunker Detective Surveys

Do you suspect a vessel is concealing fuel? In regions with high fuel theft risk, an Observater 221B Detective Survey is your solution. Our specialist surveyors in ports like Lagos, Walvis Bay, and Mombasa go beyond standard soundings.

We investigate non-nominated tanks, verify pipework integrity, check void spaces, and audit engine logbooks to uncover “magic pipes” or hidden fuel reserves. Our detailed audit reports have successfully recovered significant quantities of undeclared bunkers for Charterers and Owners across Africa.

ISO 8217 Compliance

Bunker Sampling & Quality Analysis

Poor quality fuel can destroy an engine. In African ports, ensuring compliance with ISO 8217 and MARPOL Annex VI is non-negotiable. Observater Africa surveyors oversee the sampling process to ensure a truly representative sample is drawn.

We use continuous drip sampling methods at the vessel’s manifold, seal the samples with unique tamper-proof numbers, and facilitate dispatch to accredited laboratories. Whether it’s VLSFO, HSFO, or MGO, we ensure the fuel you burn matches the specifications you ordered.

Cargo Quantity

Draft Surveys (Displacement Calculation)

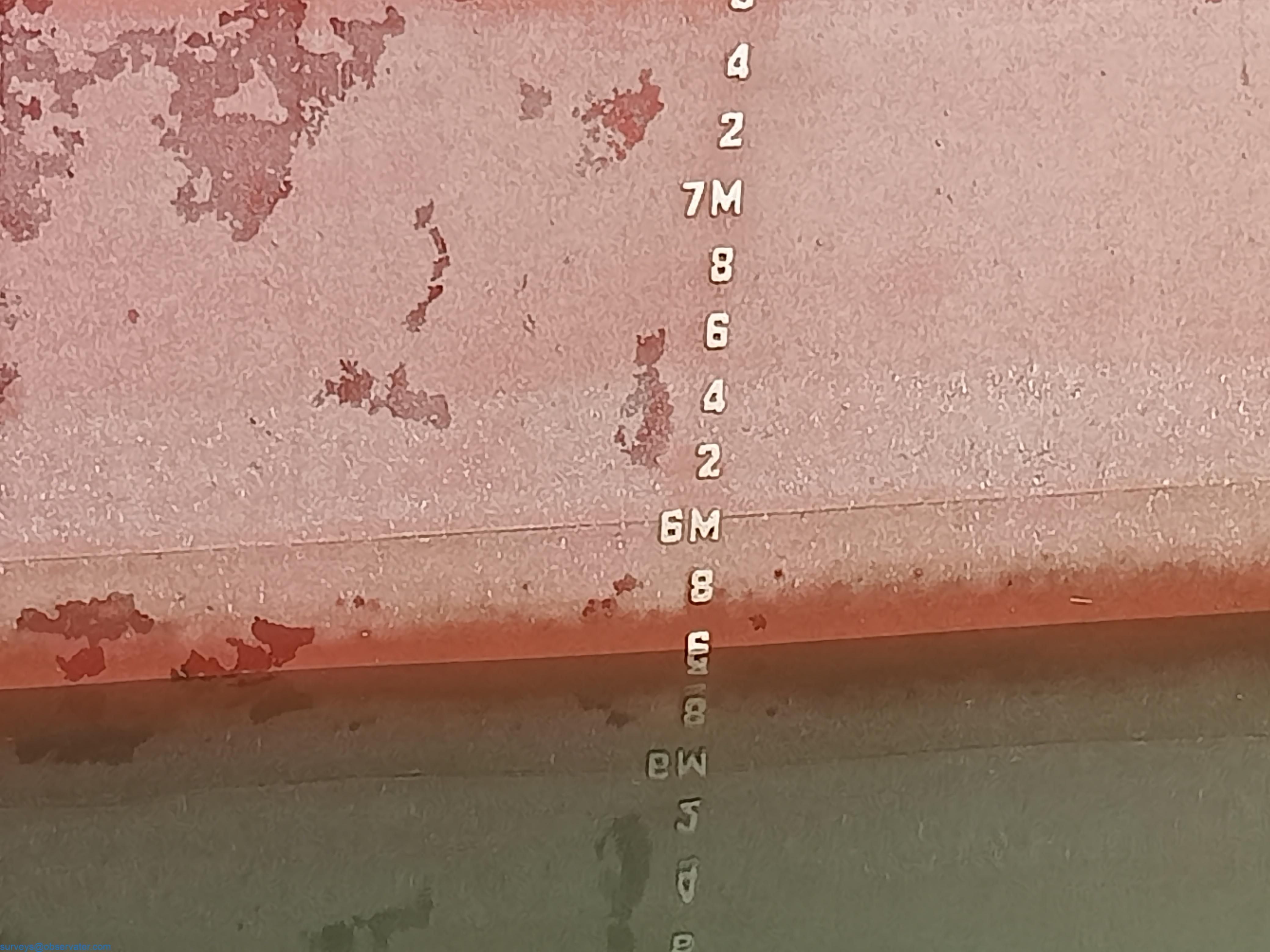

Determining cargo weight via fluid displacement is the gold standard for bulk commodities like coal, grain, and minerals. Observater Africa’s draft surveyors perform rigorous initial and final draft readings in ports like Richards Bay and Mombasa.

We apply precise corrections for water density, trim, list, and consumables (ballast/fuel) to calculate the exact cargo weight loaded or discharged. Our independent report serves as the Bill of Lading weight, protecting you from shortage claims.

Vessel Integrity

On-Hire & Off-Hire Condition Surveys

Beyond fuel, the physical condition of the vessel is critical. Our Condition Surveys document the state of the hull, cargo holds, weather decks, and hatch covers at the time of delivery or redelivery. This protects Charterers from claims for pre-existing damage and Owners from damage caused during the charter.

We provide a comprehensive photo report detailing structural integrity, coating condition, and equipment status, often combined with a Bunker ROB Survey for a complete handover package.

Fit for Load

Hold Cleanliness Inspections

Loading sensitive cargo like grain or fertilizer requires pristine cargo holds. Our surveyors inspect holds for rust scale, previous cargo residues, infestation, and odors to ensure the vessel is “fit to load.”

Failure to pass a hold inspection can lead to costly delays and off-hire time. Observater Africa’s pre-load inspections in ports like Durban and Abidjan give you the assurance that your vessel meets strict charter party and agricultural standards.

Types of Bunker Surveys We Perform in Africa

Specialized independent verification for every bunkering scenario across the continent.

On-Hire Survey

Off-Hire Survey

BQS / Stem

221B Detective

Sampling

Sludge/De-bunkering

Bunker Survey FAQ: Comprehensive Guide

Everything you need to know about bunkering operations, surveys, and risk management in African ports.

A BQS (Bunker Quantity Survey) is performed during the supply of new fuel to verify the delivered amount against the delivery note (BDN). It focuses on the specific stem. An On-Hire Survey is performed when a vessel is chartered; it measures the total fuel already on board (ROB) in all tanks to establish the starting quantity for the Charter Party agreement.

Yes. Observater Africa has extensive experience in the offshore STS (Ship-to-Ship) zones and anchorages of Lomé (Togo) and Lagos (Nigeria). Our surveyors are equipped to board offshore and supervise high-volume transfers.

A 221B survey is a forensic audit of a vessel’s fuel. Unlike a standard survey, it involves investigating non-nominated tanks, void spaces, sounding pipe integrity, and engine logbooks to uncover concealed or “magic pipe” fuel that hasn’t been declared.

The “Cappuccino Effect” occurs when air is blown into the fuel, creating froth that inflates volume readings. Our surveyors monitor line pressures, observe the fuel surface for bubbles, and perform checks before and after the settling period to detect and correct for aerated fuel.

Yes. Our Pan-African network covers over 85 ports. From Walvis Bay (Namibia) to Port Sudan and Maputo (Mozambique), we can deploy a surveyor to almost any commercial port in Africa with minimal notice.

The surveyor acts as an independent witness. They gauge the barge and receiving vessel tanks before and after pumping, calculate quantities based on temperature/density, witness sampling, and ensure the BDN accurately reflects the transfer.

If a shortage is identified, we immediately issue a Letter of Protest (LOP) to the supplier. We gather all evidence (density logs, sounding tapes, pressure records) to support your claim. Our independent report acts as the primary evidence in resolving the dispute.

We strictly follow ISO 8217 and MARPOL Annex VI guidelines. We use continuous drip sampling methods at the vessel’s manifold to ensure the sample is truly representative of the entire bunkering operation.

Yes, bunkering is a 24/7 operation, and so are we. Our surveyors are available around the clock, including weekends and public holidays, to ensure no delays to your vessel’s schedule.

This survey is conducted when a vessel is redelivered from a Charterer back to the Owner. It determines the exact fuel quantity remaining on board (ROB) at the specific time of redelivery to finalize financial accounts.

Absolutely. Volume changes with temperature. We measure the temperature of the fuel in the tanks and verify the density (often using a hydrometer) to calculate the correct weight in Metric Tonnes (Vacuum) as per ASTM tables.

Yes. Observater Africa is a fully independent inspection company. We do not sell fuel and are not affiliated with any bunker suppliers. Our loyalty is solely to the client appointing us to ensure an unbiased report.

Yes, we verify the quantity of sludge or slops discharged ashore or to a barge, ensuring the vessel receives a correct certificate for MARPOL record-keeping.

A “magic pipe” is a hidden or modified pipe used to bypass meters or divert fuel to non-nominated tanks. Our 221B detective surveyors are trained to trace pipework and identify these illicit modifications.

We provide preliminary reports (field reports) immediately upon completion of the survey on board. The final typed report with all photos and documents is typically issued within 24 hours.

Yes, in ports where Mass Flow Meters are used, our surveyors verify the MFM seals, check the zero-start/stop readings, and ensure the meter profile is valid for the delivery.

This is common. Our surveyor will investigate the discrepancy, re-sound tanks if necessary, check calibration tables, and issue a Note of Protest if the difference exceeds the allowable variance (usually 0.5%).

Yes, we conduct quantity surveys for bulk Lube Oil deliveries and ROB verification for On/Off-Hire condition surveys.

VCF is a multiplier found in ASTM tables (like Table 54B) used to convert the observed volume of fuel at its current temperature to a standard volume at 15°C. This is crucial for accurate weight calculation.

Yes, we often include Fresh Water ROB verification as part of our standard On-Hire and Off-Hire Condition Surveys.

Yes, Durban is one of our primary hubs. We have a dedicated team of surveyors available 24/7 for BQS and ROB surveys at all terminals and anchorages in Durban.

We collect and verify the Bunker Delivery Note (BDN), Certificate of Quality, Vessel Experience Factor (VEF) records, last 10 bunker reports, and the Oil Record Book.

Yes, if a vessel needs to offload off-spec fuel or reduce weight, we supervise the de-bunkering process to certify the quantity removed.

A line sample taken at the ship’s manifold during bunkering is the only legally binding evidence of the quality of fuel as it passed from the supplier to the ship.

VEF is a historical ratio comparing the vessel’s calculated figures to the shore/barge figures over previous bunkering operations. It helps determine if the vessel typically receives more or less than stated, aiding in dispute resolution.

Yes, we use water-finding paste on the sounding tape for every tank to detect free water at the bottom of fuel tanks.

Yes, we regularly service vessels at Walvis Bay anchorage for both BQS and On/Off-Hire surveys via launch boat.

Unpumpable fuel (or sludge) is estimated based on the tank geometry and suction levels. However, in detective surveys, we verify if “unpumpable” volumes are exaggerated to hide usable fuel.

While we perform the physical sampling, we can arrange for the samples to be sent to accredited ISO 17025 laboratories for full chemical analysis.

Simply email our 24/7 operations desk at ops@observater.com with your vessel details, port, and ETA. We will provide a competitive quote and confirm surveyor availability immediately.

Appoint an Independent Bunker Surveyor in Africa

Don’t leave your fuel quantity to chance. Contact Observater Africa’s 24/7 desk to appoint a surveyor at our comprehensive network of African ports and secure your bunkering operation today.

Request Bunker Survey